Exair specialises in innovative compressed air solutions that enhance performance at the point of use while significantly reducing energy consumption and noise levels. Designed for industrial environments, Exair products replace inefficient open pipe systems with engineered solutions that deliver precise, controlled airflow for cleaning, cooling, conveying, and static elimination applications.

At Comvac, we supply a comprehensive range of Exair products that integrate seamlessly into existing compressed air systems. From air knives and nozzles to cabinet coolers and vacuum generators, Exair solutions are engineered to improve process efficiency, workplace safety, and overall system reliability. With no moving parts in many designs, Exair products offer long service life with minimal maintenance—making them a smart, cost-effective choice for modern industrial operations.

Key Benefits

-

Reduces compressed air consumption and operating costs

-

Low-noise solutions improve workplace safety

-

Improves process efficiency at the point of use

-

Maintenance-free designs with no moving parts

-

Simple integration into existing systems

-

Suitable for a wide range of industrial applications

Air Amplifiers

Efficient Air Movement for Smoke, Heat, and Fume Control

Exair Air Amplifiers provide a simple, cost-effective solution for moving large volumes of air using a minimal amount of compressed air. By drawing in and amplifying surrounding ambient air, these units generate high-velocity airflow suitable for ventilation, cooling, fume extraction, and circulation applications.

With no moving parts and no electrical requirements, Air Amplifiers offer long service life and reliable performance in demanding industrial environments. They are commonly used for removing welding smoke, cooling hot components, distributing heat within moulds, and ventilating confined or enclosed spaces—all while maintaining low noise levels and energy efficiency.

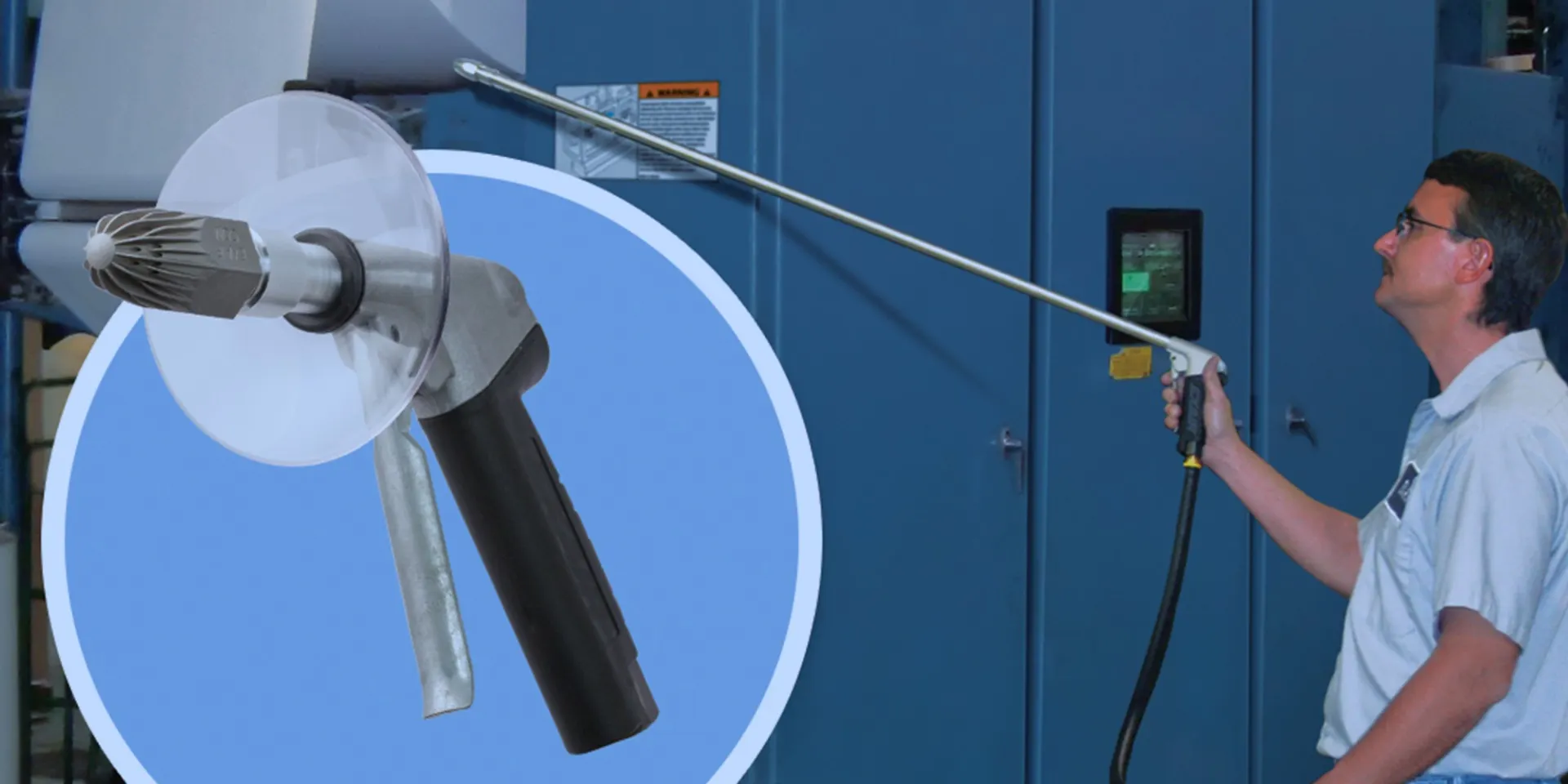

Air Guns

Safe, efficient blow-off solutions for industrial cleaning applications

EXAIR Safety Air Guns are designed to deliver powerful, controlled blow-off for cleaning, drying, and debris removal while maintaining the highest safety standards. Engineered to meet OSHA noise and pressure requirements, these air guns reduce harmful noise levels and eliminate the risk of dangerous dead-end pressures by preventing blockage at the nozzle.

Built for durability and operator comfort, EXAIR air guns feature ergonomic designs suitable for continuous use in industrial environments. They are compatible with EXAIR engineered air nozzles to maximise efficiency and reduce compressed air consumption. A wide range of extensions, chip shields, and accessories are available to improve reach, safety, and versatility, making EXAIR Safety Air Guns a reliable solution for workshops, production lines, and maintenance operations.

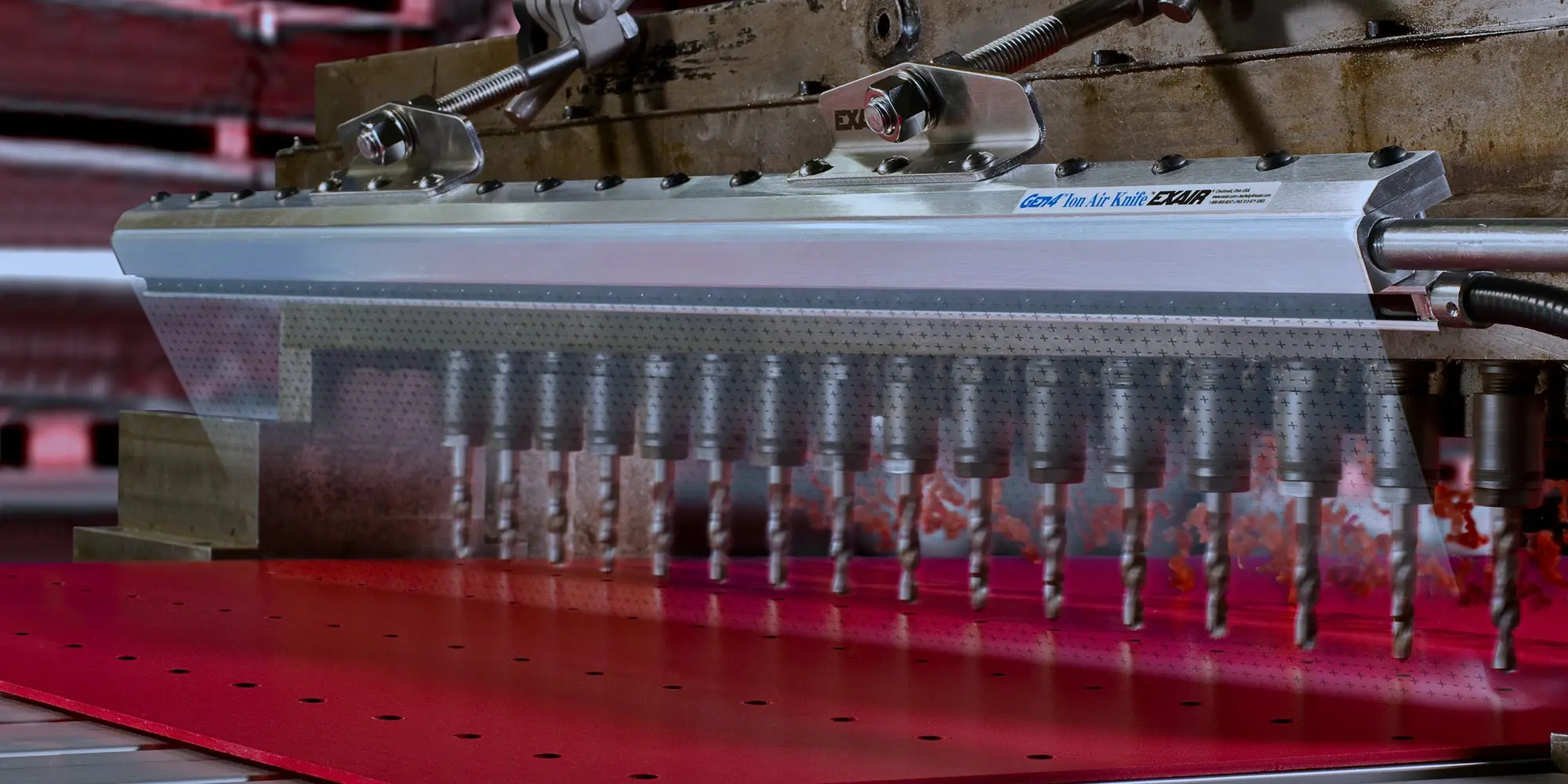

Air Knives

Uniform, high-performance airflow for industrial cleaning, drying, and blow-off

EXAIR Air Knives deliver a powerful, uniform curtain of air designed to replace inefficient open pipe blow-off methods. By amplifying surrounding air, they generate high-velocity airflow using significantly less compressed air, resulting in improved efficiency and reduced operating costs.

With no moving parts and no electrical requirements, Air Knives provide reliable, maintenance-free operation in demanding industrial environments. They are commonly used for drying parts, removing liquids or debris, cooling products, and separating materials on conveyors. Available in aluminium and stainless steel, EXAIR Air Knives are suitable for a wide range of applications, including food processing, packaging, manufacturing, and heavy industry.

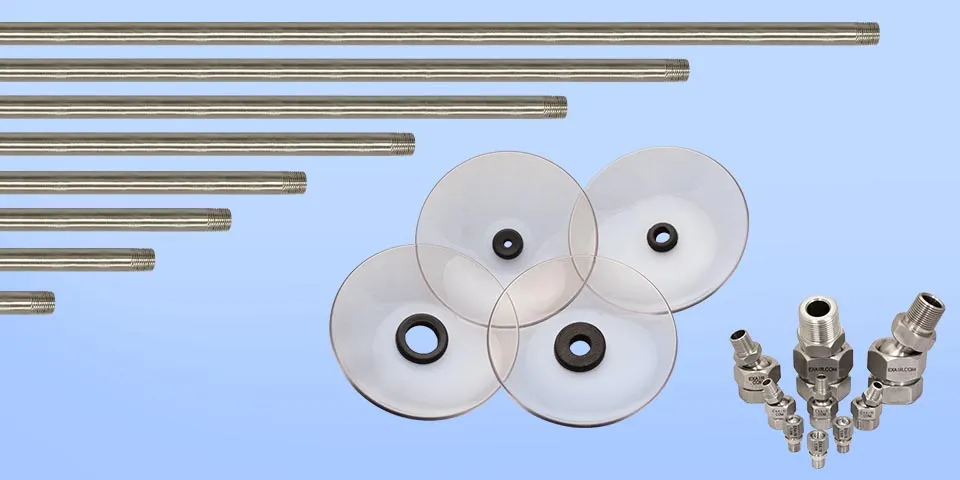

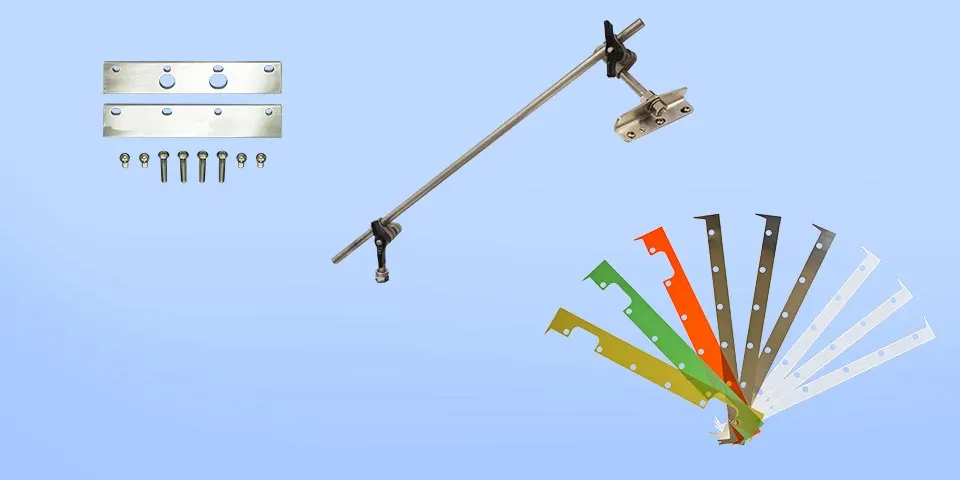

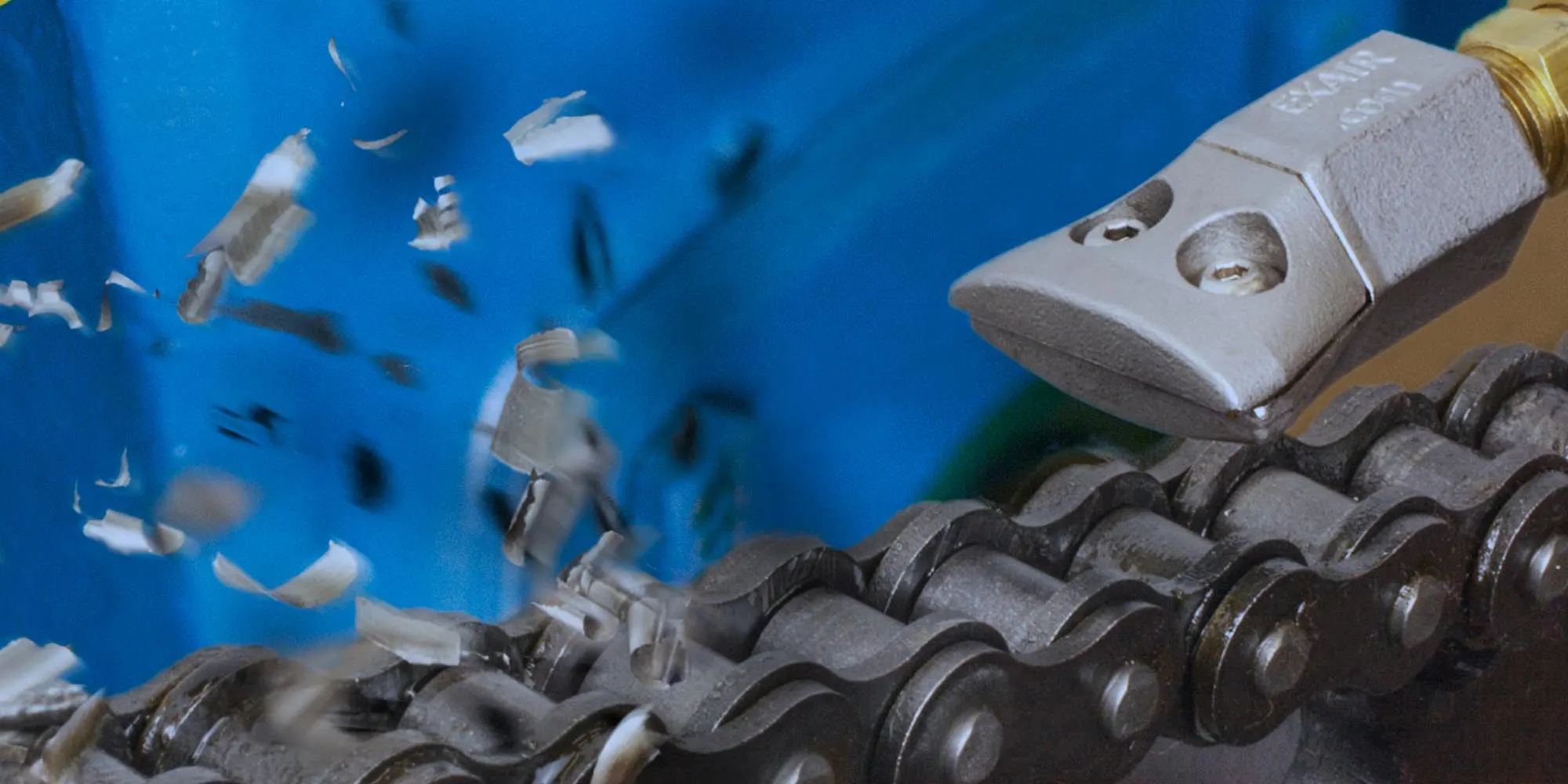

Air Nozzles & Jets

Targeted, low-noise airflow with reduced compressed air consumption

EXAIR Air Nozzles and Jets provide precise, controlled blow-off for cleaning, drying, and cooling applications. Engineered to replace open pipes and drilled tubing, these nozzles significantly reduce compressed air usage while delivering powerful and effective airflow.

Designed to meet OSHA noise and pressure standards, EXAIR nozzles improve workplace safety and efficiency. Their durable construction and optimised air patterns ensure consistent performance across a wide range of industrial applications, from light maintenance tasks to heavy-duty production environments.

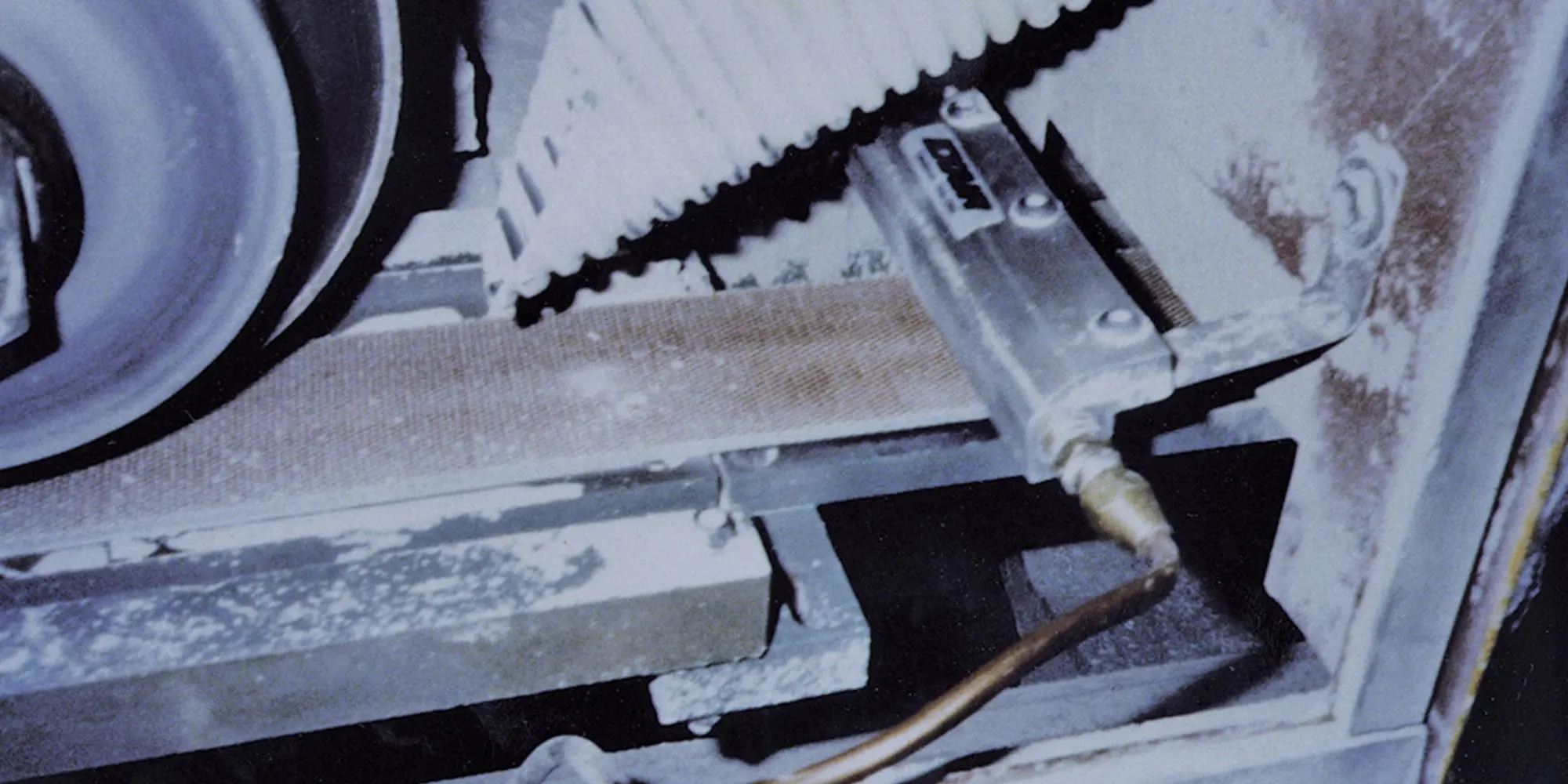

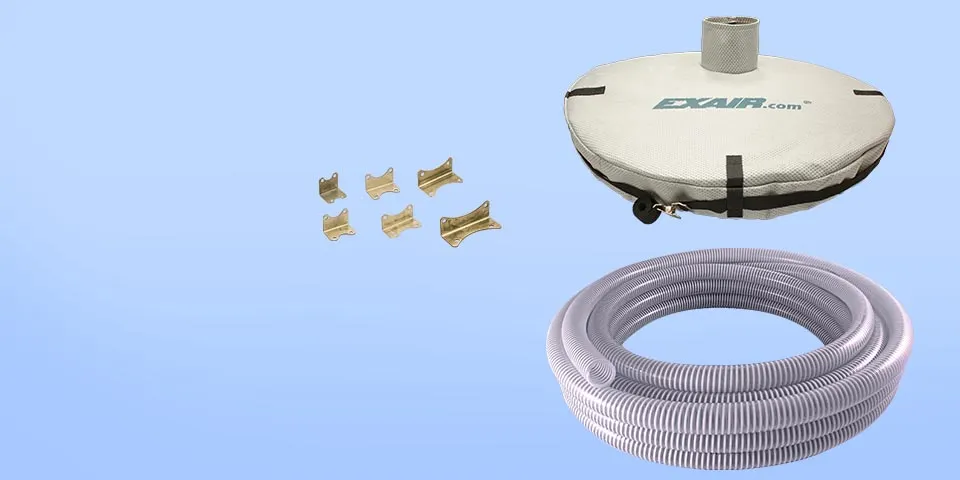

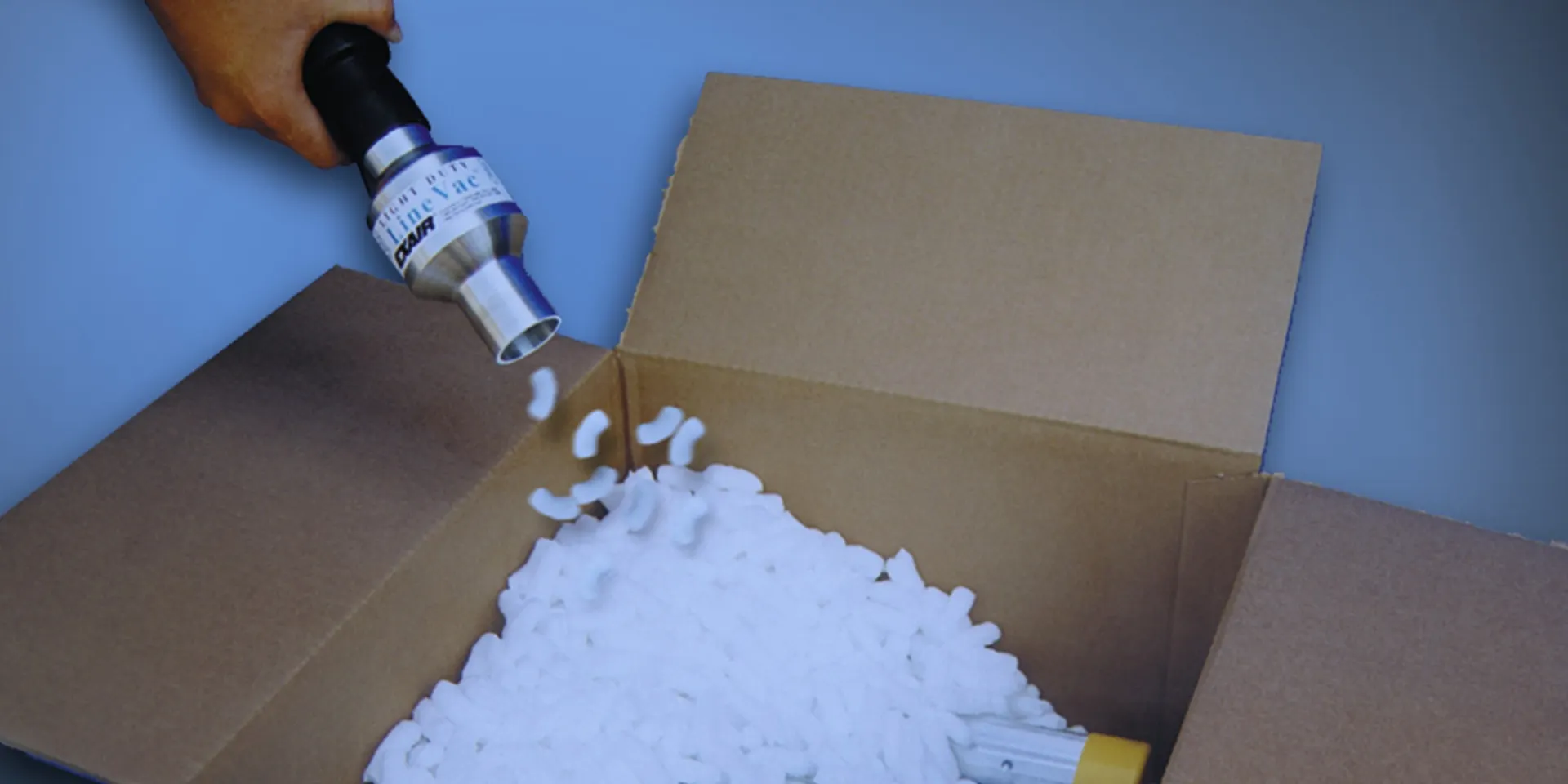

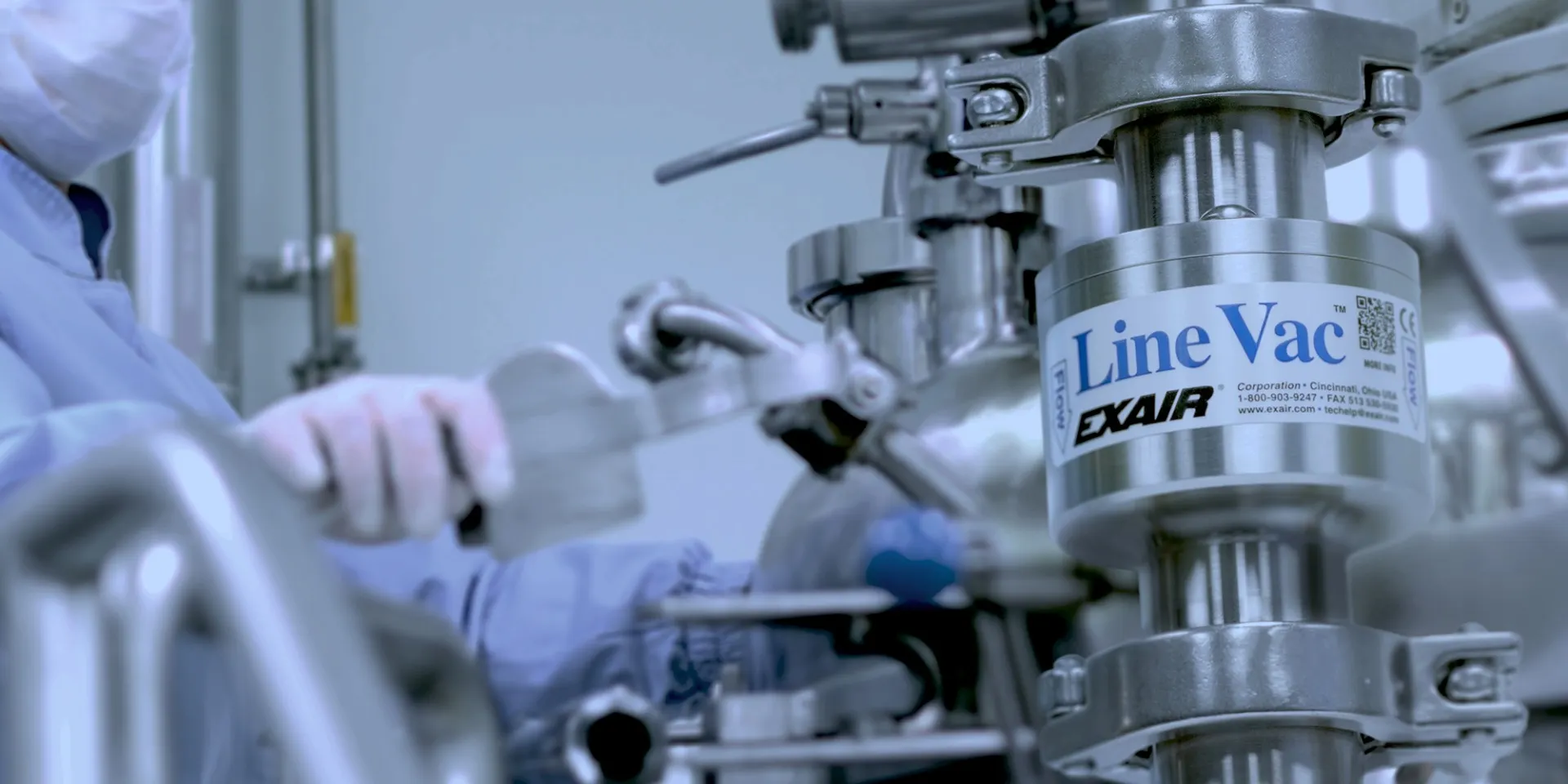

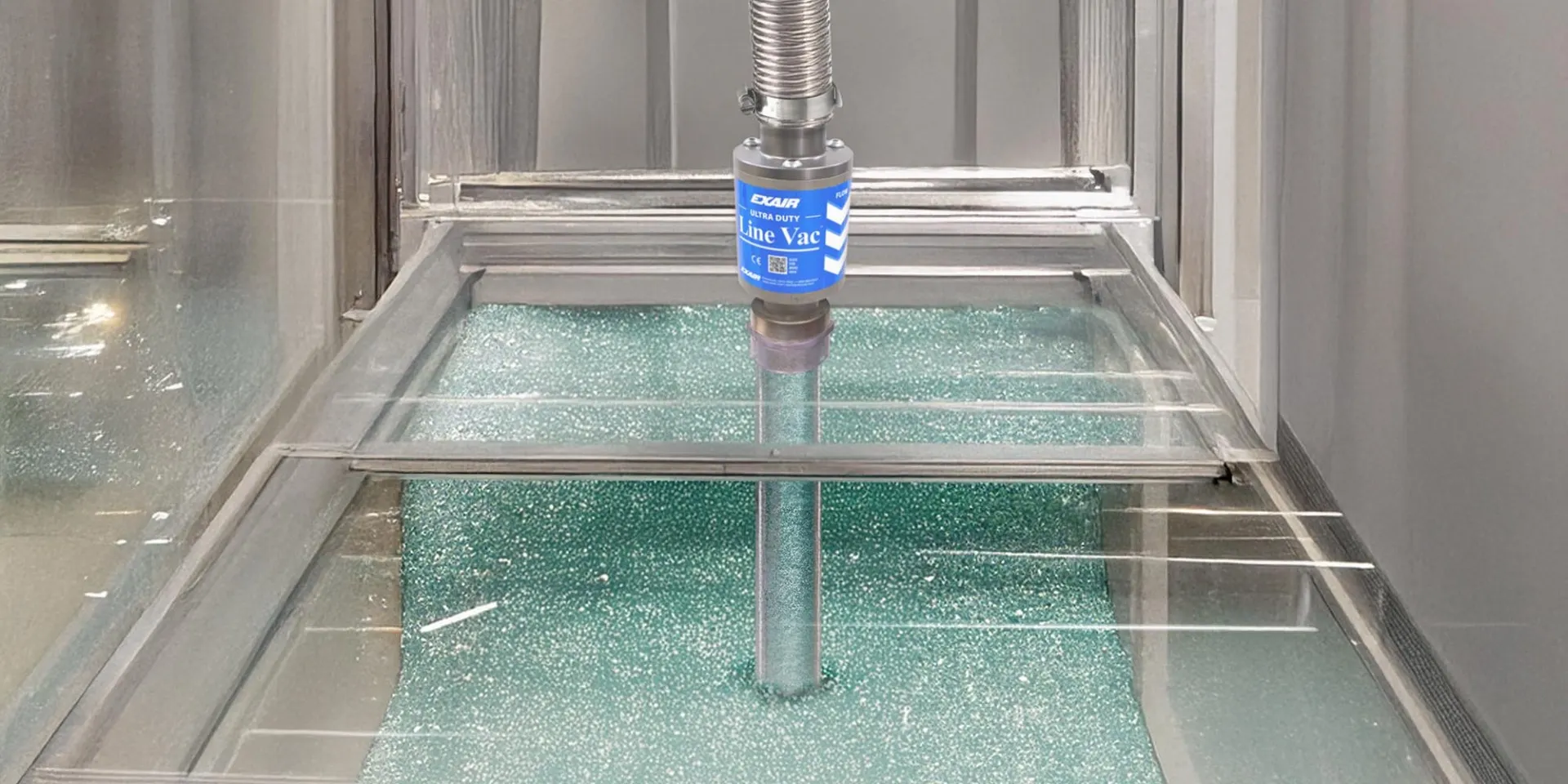

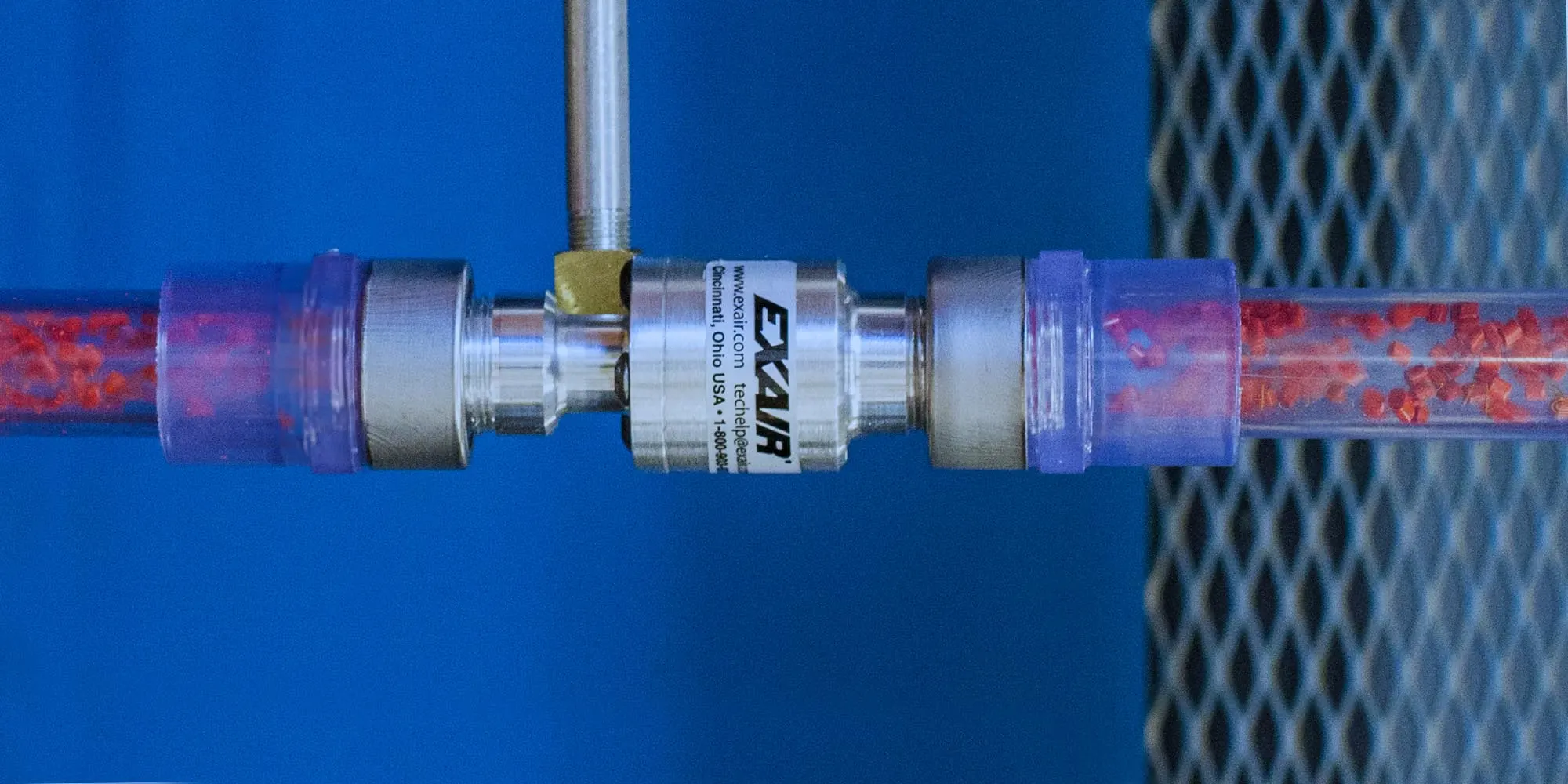

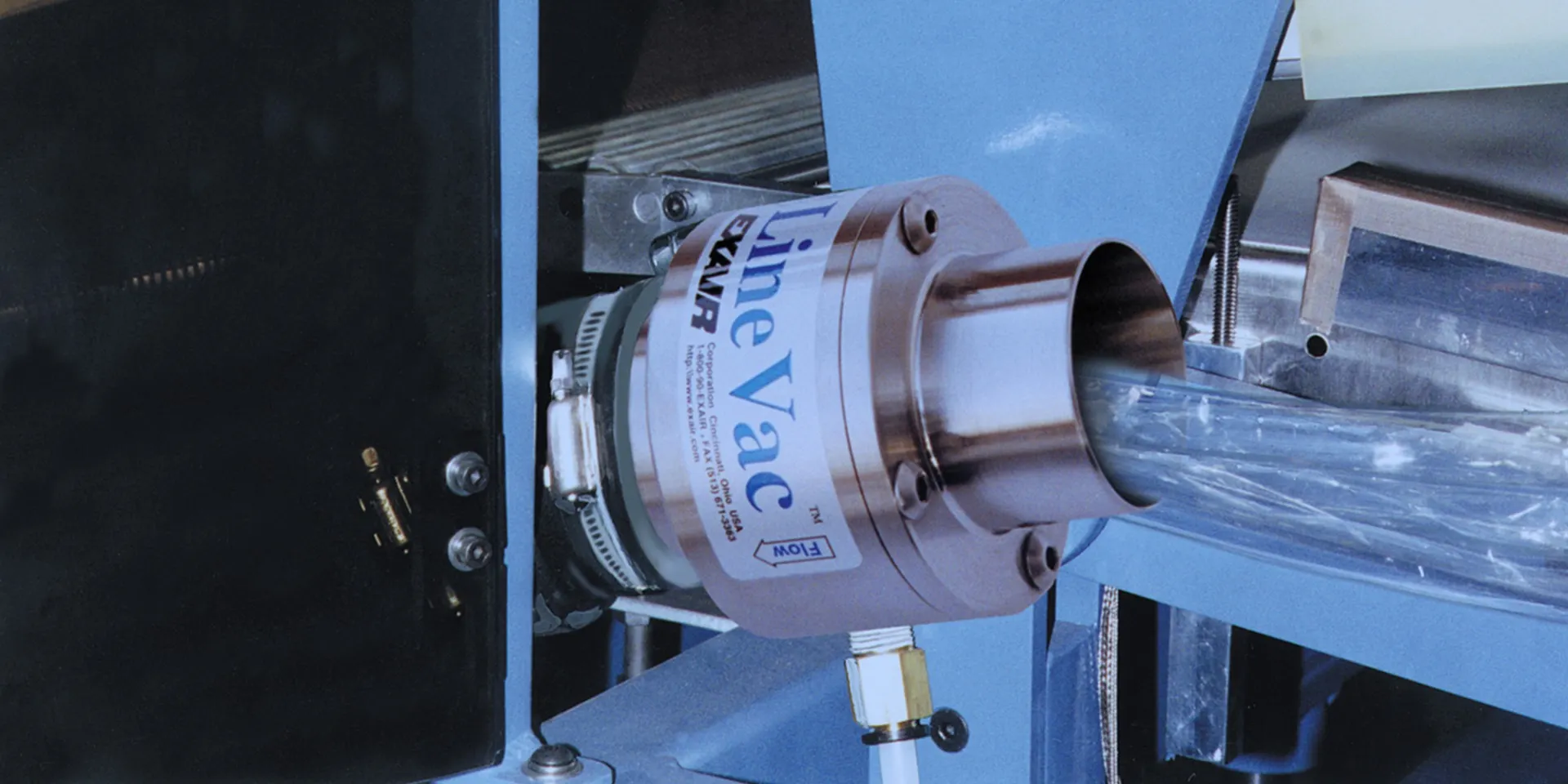

Air Operated Conveyors

Efficient material conveying powered by compressed air

EXAIR Air Operated Conveyors use high-velocity compressed air to transport materials such as chips, scrap, pellets, and bulk solids. With no moving parts and no electrical components, these conveyors provide a reliable and low-maintenance solution for material handling in industrial environments.

Ideal for transferring materials over distances or lifting them vertically, air-operated conveyors improve productivity while reducing mechanical complexity and downtime.

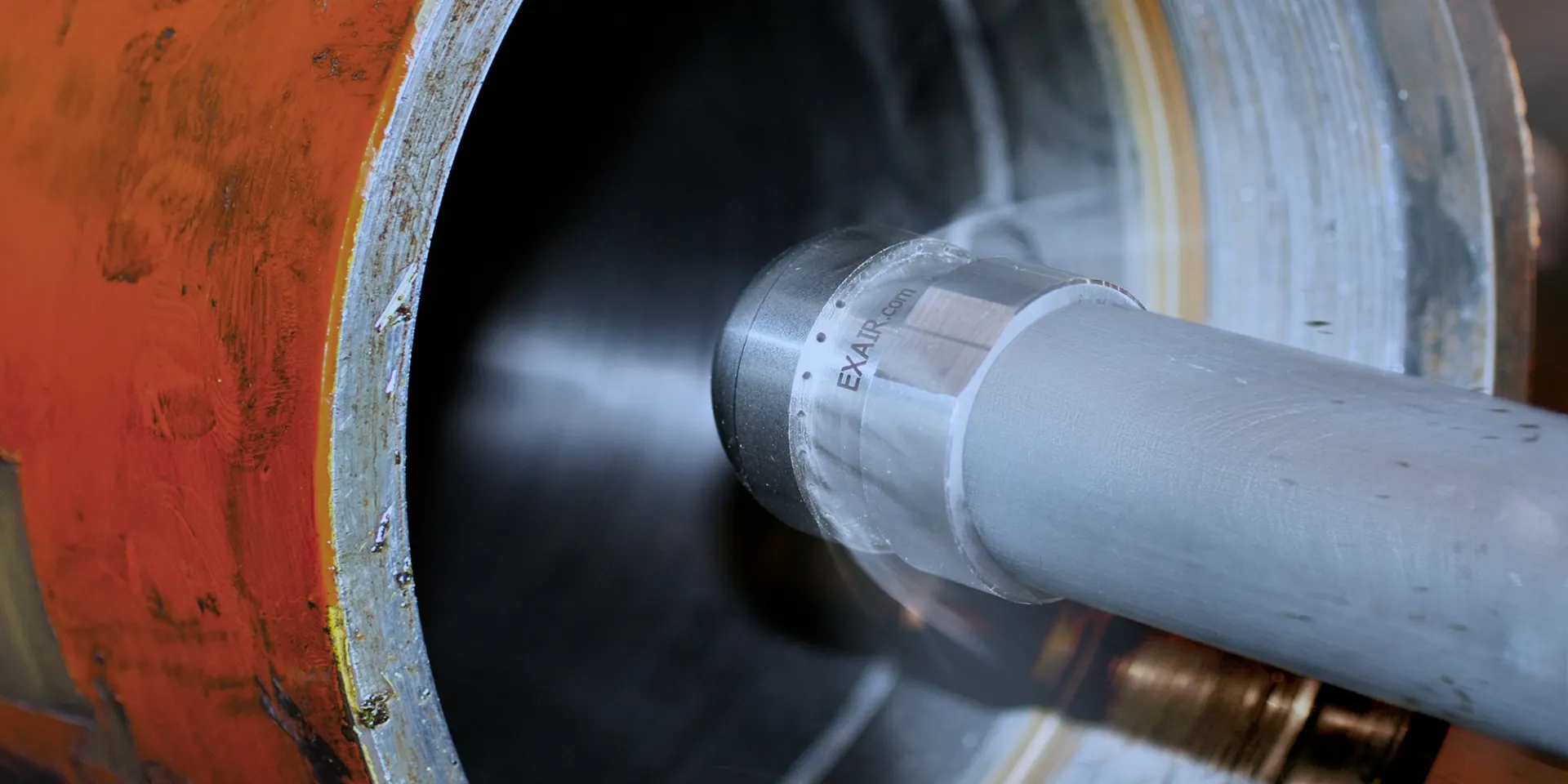

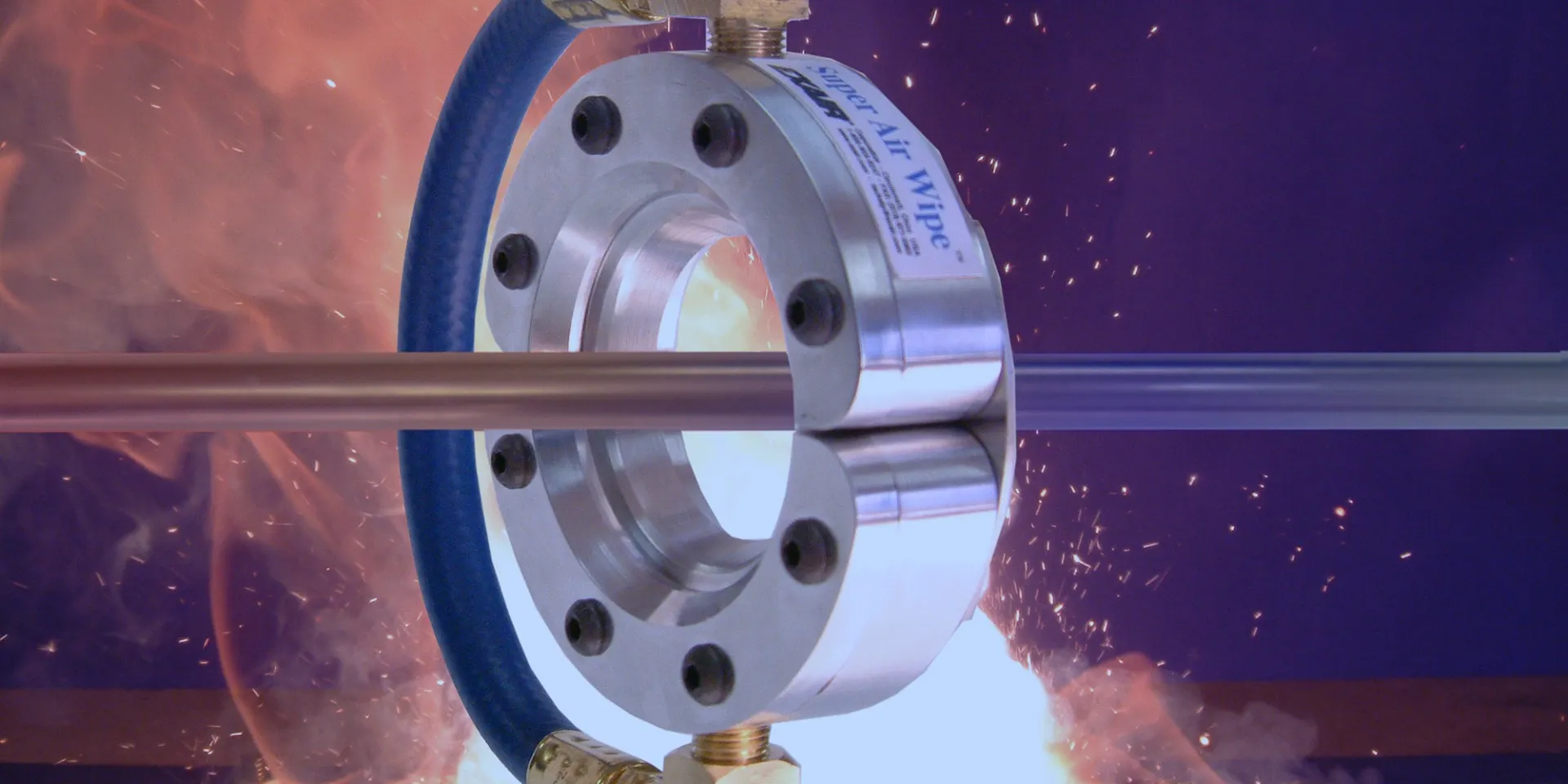

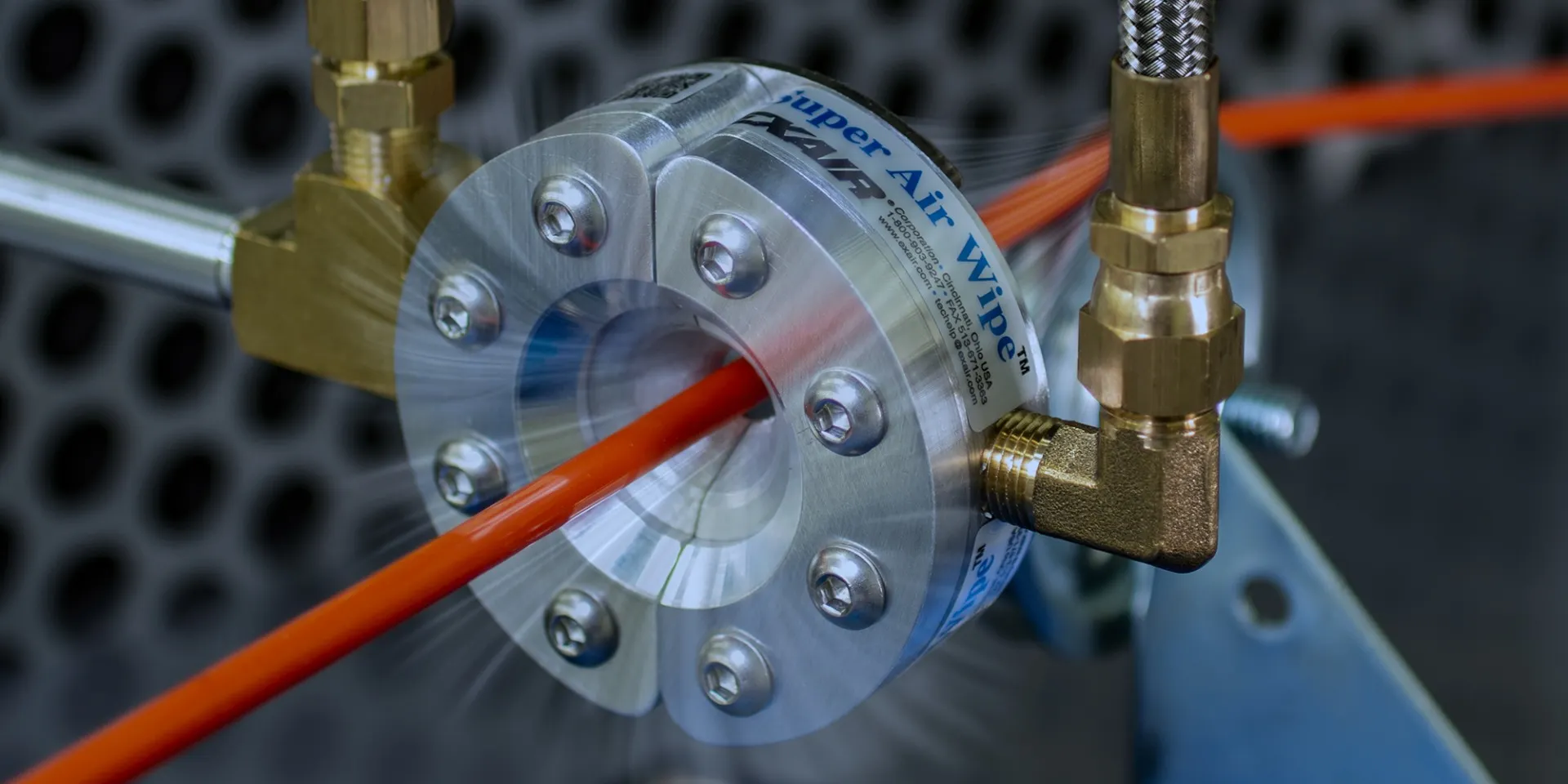

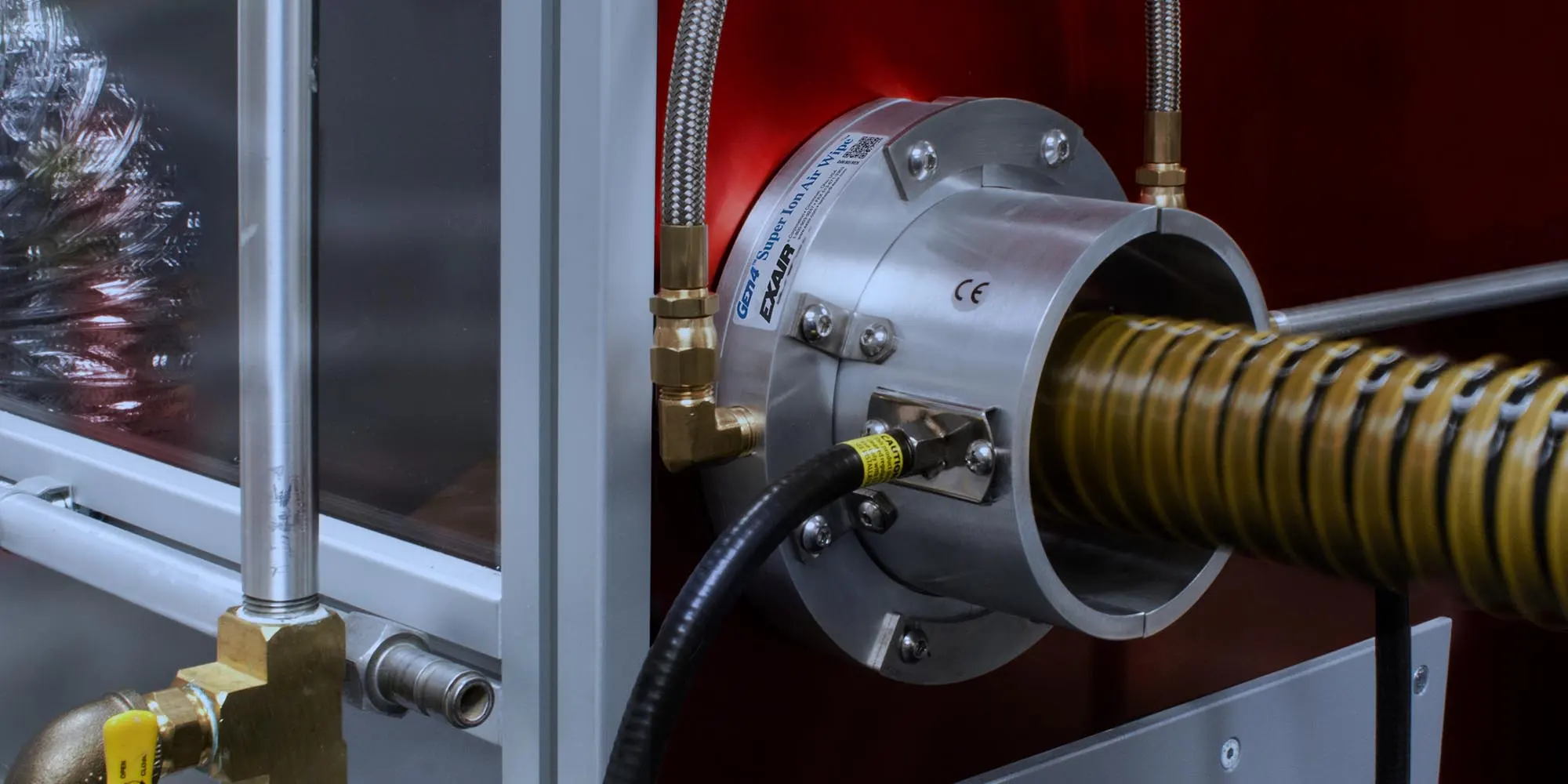

Air Wipes

360-degree airflow for cleaning and drying cylindrical products

EXAIR Air Wipes deliver uniform, high-velocity airflow around cylindrical objects such as pipes, tubes, cables, and extrusions. By evenly removing water, oil, dust, and debris, they ensure consistent results while using less compressed air than traditional methods.

Their simple, maintenance-free design makes them ideal for continuous operation in production lines where efficiency and reliability are critical.

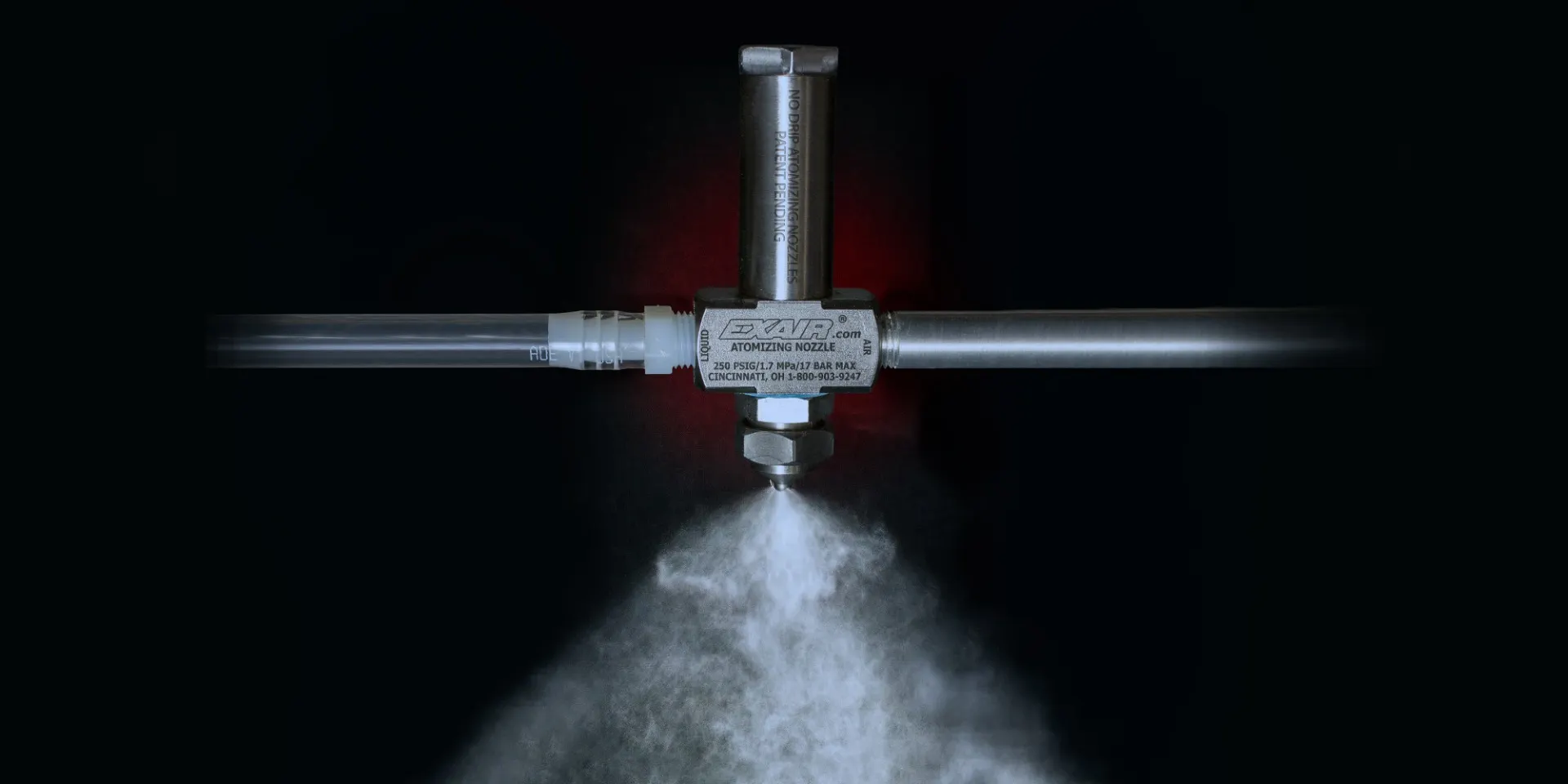

Atomizing Nozzles

Precision Spray Solutions for Industrial Applications

Atomizing Nozzles are engineered to deliver controlled, efficient liquid dispersion for a wide range of industrial processes. Designed for reliability and consistency, they improve coverage, reduce waste, and enhance process efficiency across washing, cooling, coating, and dust control applications.

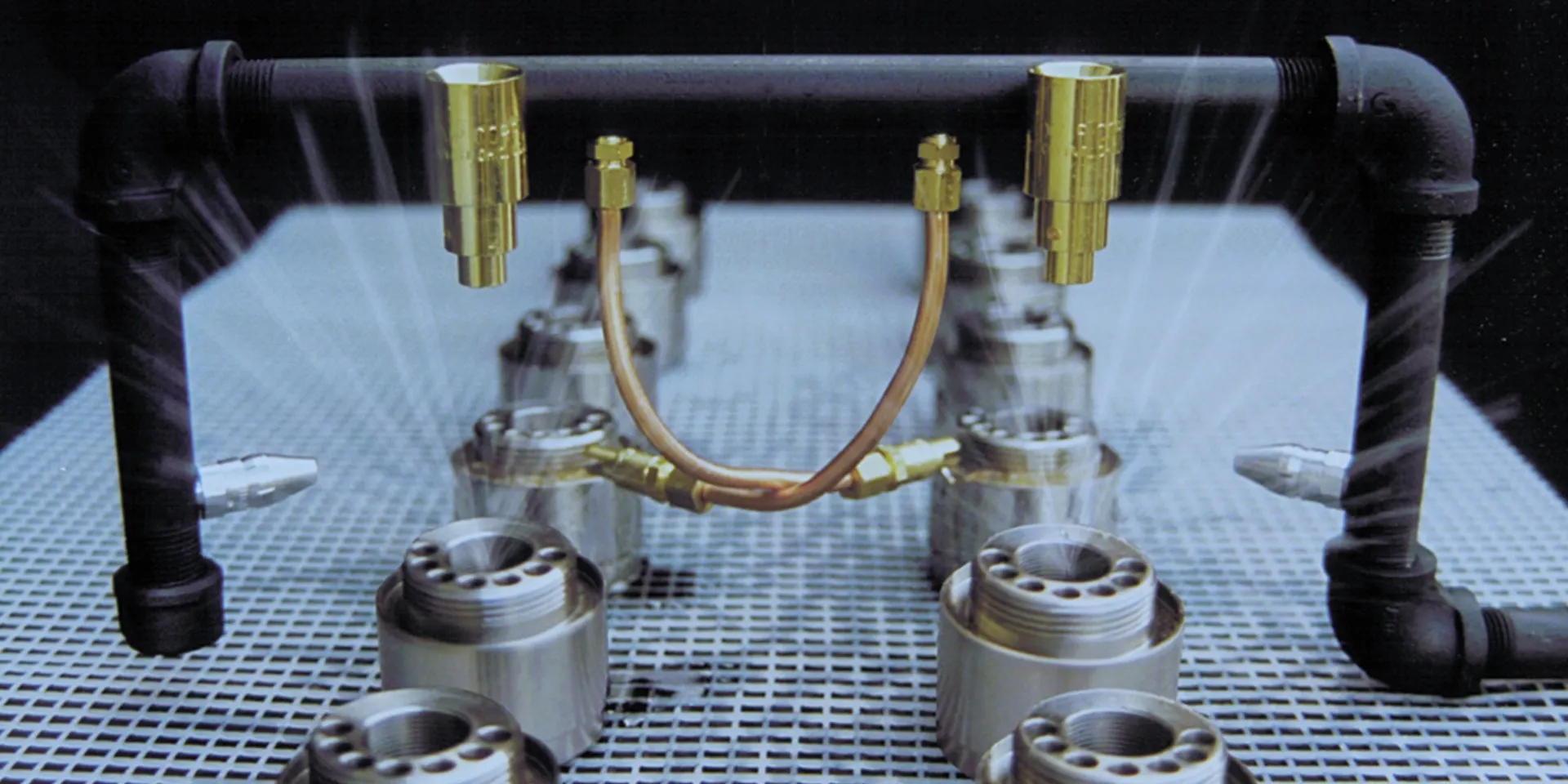

Air Atomizing Spray Nozzles

Air Atomizing Spray Nozzles combine compressed air with liquid to produce a fine, uniform mist. Available in multiple configurations and spray patterns, they provide precise control over droplet size and flow rate. These nozzles are ideal for applications requiring consistent coverage, including surface coating, part washing, evaporative cooling, lubrication, and dust suppression.

Liquid Atomizing Spray Nozzles

Liquid Atomizing Spray Nozzles are general-purpose solutions designed to disperse liquids without the use of compressed air. Offered in a variety of spray patterns, they are well suited for applying water, detergents, rinse aids, chemicals, pesticides, herbicides, and other process fluids. Their robust design ensures dependable performance in demanding industrial environments.

Together, these atomizing nozzle solutions help optimise fluid usage, improve process control, and maintain high operational standards in production facilities.

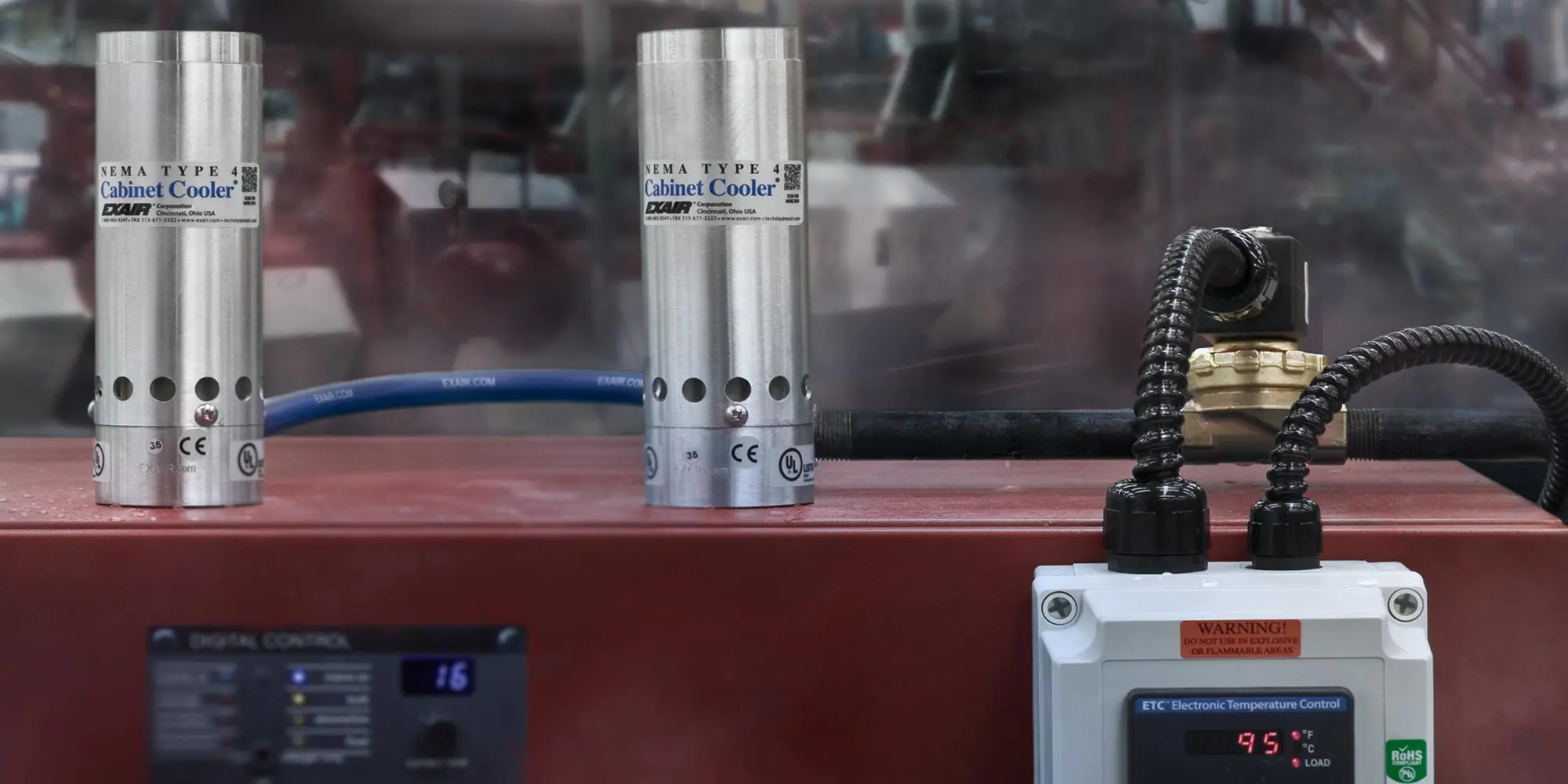

Cabinet Coolers

Maintenance-free enclosure cooling without electricity

EXAIR Cabinet Coolers provide a simple and reliable way to cool electrical enclosures and control panels using compressed air. By creating a vortex of cold air, they maintain safe operating temperatures without the need for fans, refrigerants, or electrical connections.

Designed for harsh industrial environments, Cabinet Coolers protect sensitive electronics from heat, dust, and moisture while requiring virtually no maintenance.

Cold Gun

Cold Guns for Spot Cooling Without Electricity

EXAIR Cold Guns provide an instant, low-cost solution for cooling hot parts, tools, and processes. Using compressed air only, they deliver a precise stream of cold air without refrigerants, moving parts, or electricity. Cold Guns are ideal for machining operations, heat-sensitive materials, tool cooling, and preventing heat-related production issues.

Key benefits include fast temperature reduction, easy installation, quiet operation, and maintenance-free performance, making them a reliable solution for industrial spot cooling applications.

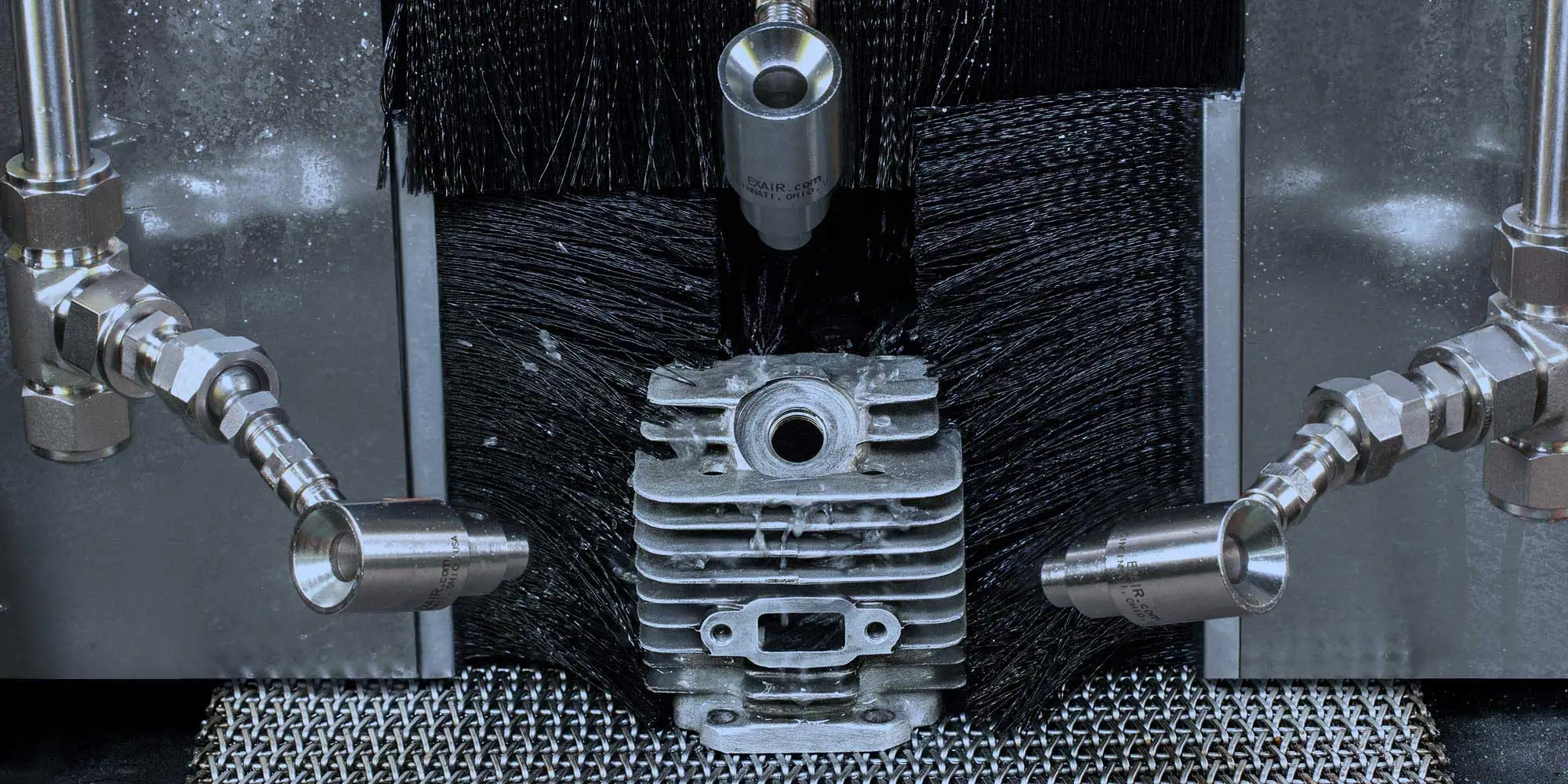

Industrial Housekeeping Optimisation

Efficient Air Solutions for Safer, Cleaner Workspaces

Industrial housekeeping optimisation focuses on improving cleanliness, safety, and efficiency using engineered compressed air products. EXAIR solutions help eliminate debris, chips, dust, and liquid accumulation without excessive air consumption or unsafe practices.

By replacing open pipes and inefficient blowoff methods, facilities achieve reduced air usage, improved operator safety, lower noise levels, and compliance with OSHA standards. Optimised housekeeping leads to improved productivity, reduced downtime, and a safer working environment.

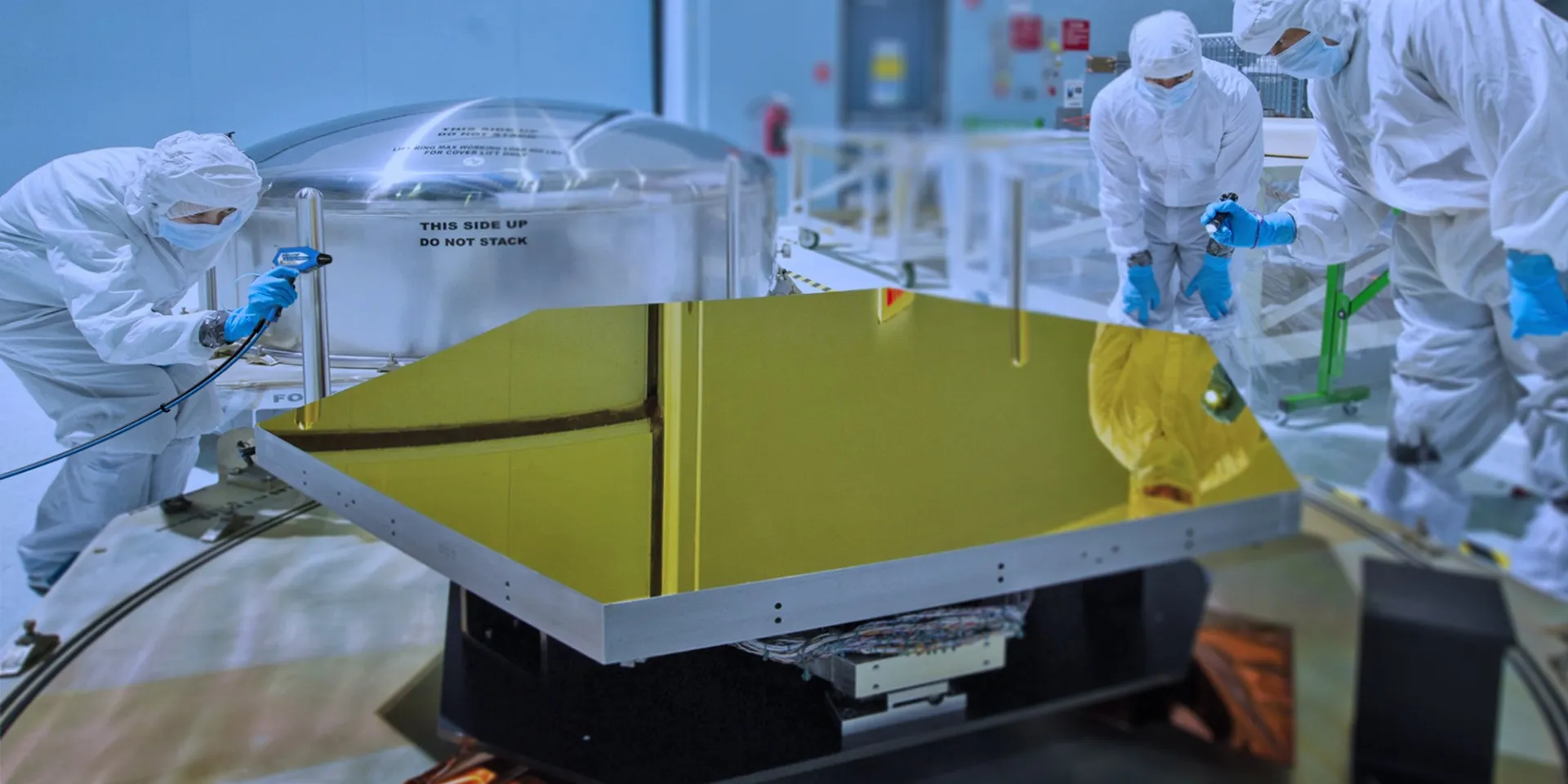

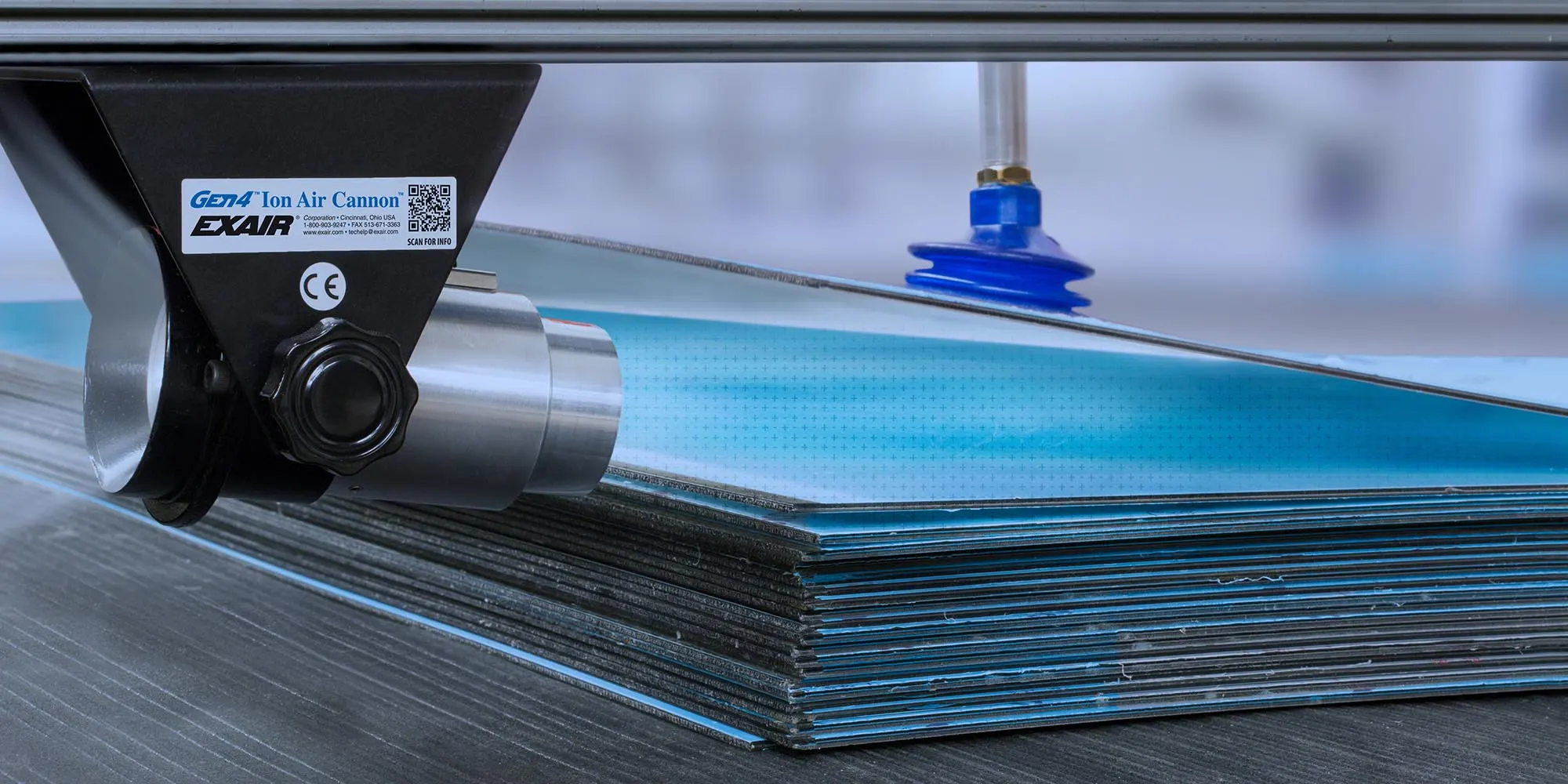

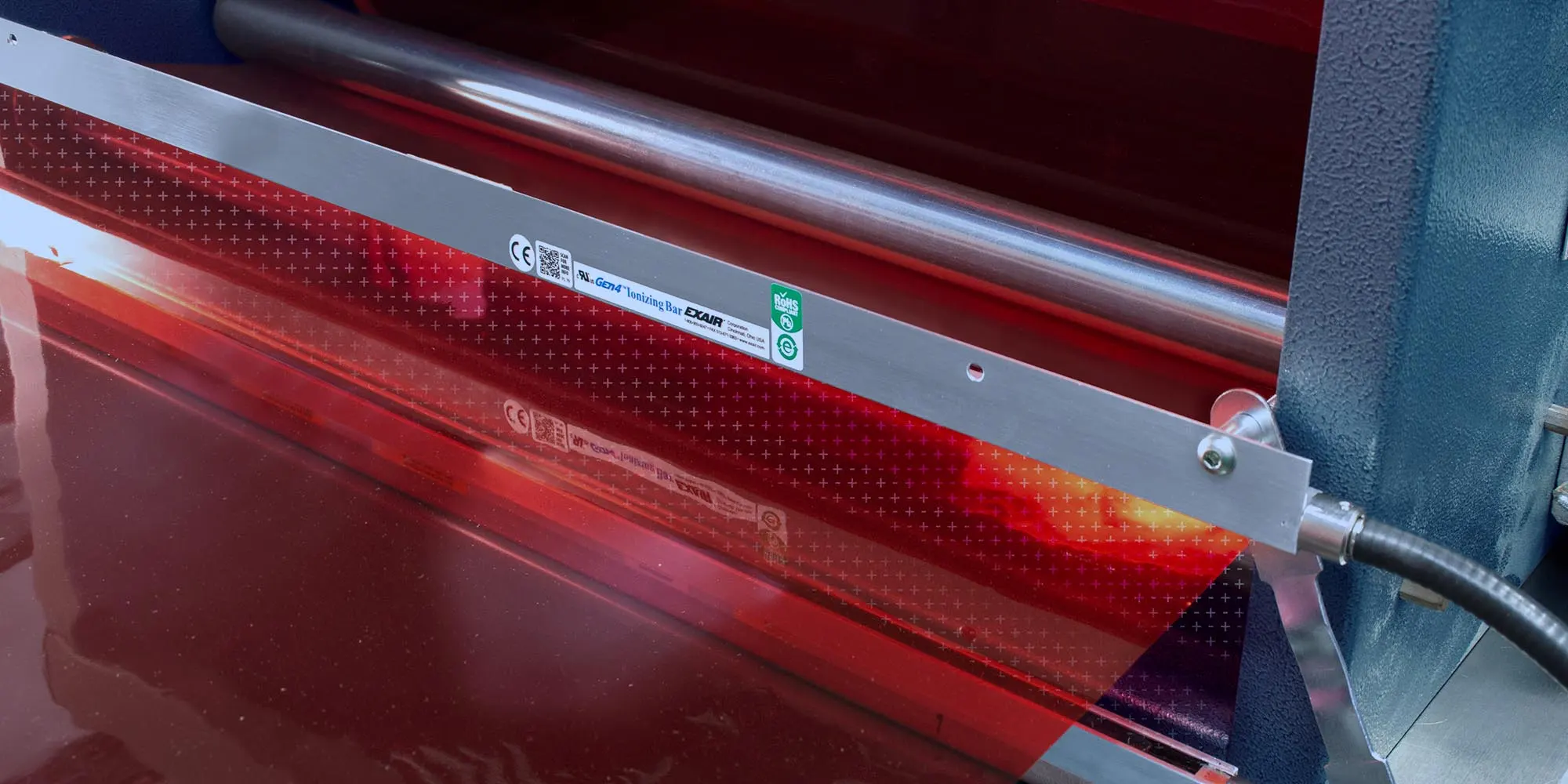

Static Eliminators

Effective Static Control for Production Reliability

EXAIR Static Eliminators neutralise static electricity on surfaces, materials, and products to prevent dust attraction, product defects, and processing disruptions. They are commonly used in printing, packaging, plastics, textiles, and electronics manufacturing.

Available in a range of formats including ionising air guns, bars, blowers, and nozzles, static eliminators improve product quality, increase throughput, and reduce waste caused by static-related issues.

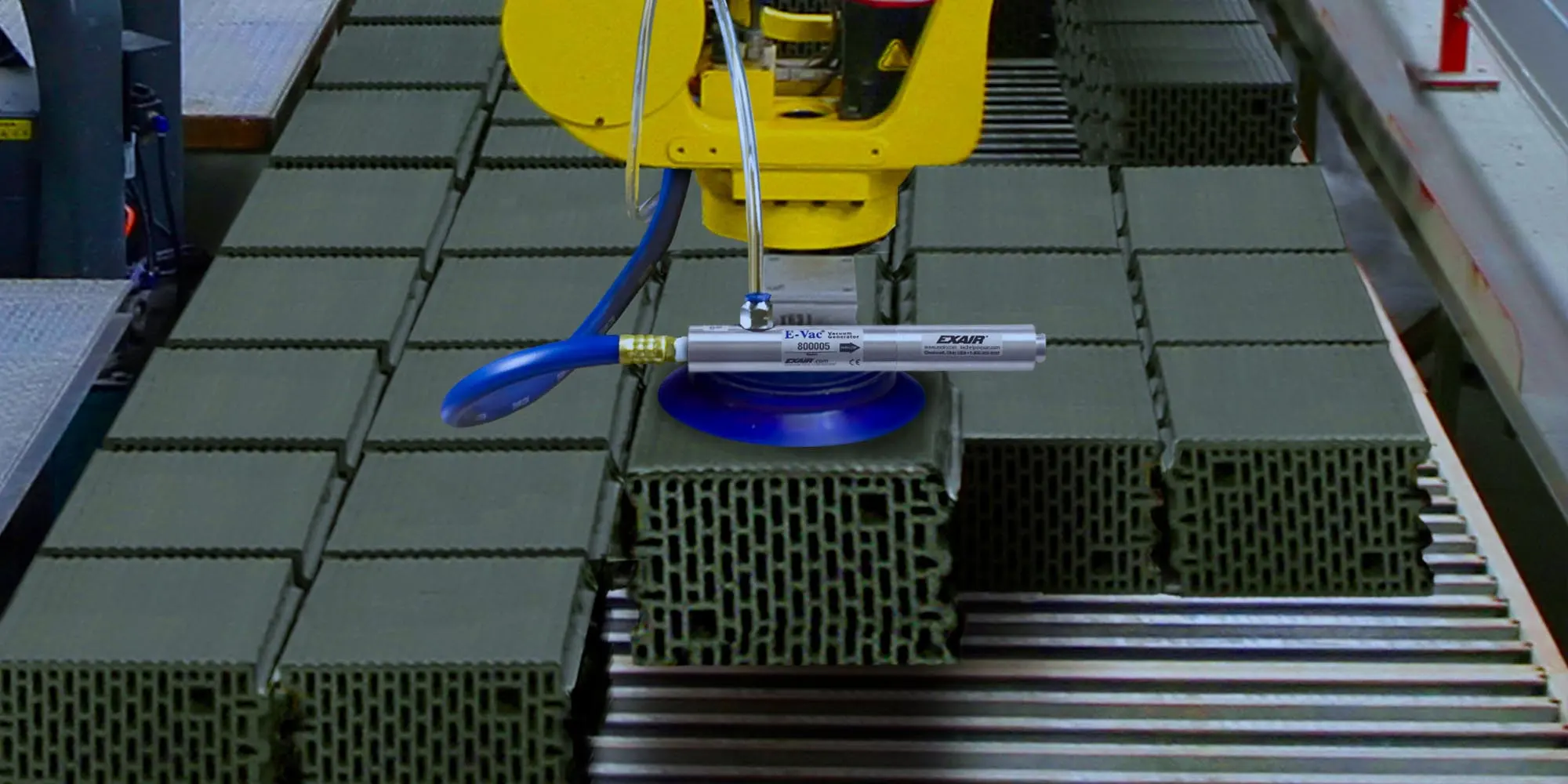

Vacuum Generators

Compact, High-Efficiency Vacuum Solutions

EXAIR Vacuum Generators create powerful vacuum using compressed air with no moving parts. Designed for lifting, conveying, holding, and material handling applications, they provide reliable performance in demanding industrial environments.

Their compact design allows easy integration into existing systems while delivering fast response times, high vacuum levels, and minimal maintenance. Ideal for automation, packaging, robotics, and pick-and-place operations.

Vortex Tubes

Instant Hot and Cold Air from Compressed Air

EXAIR Vortex Tubes convert compressed air into two separate streams of hot and cold air without electricity or moving parts. They are widely used for enclosure cooling, cabinet conditioning, process cooling, and heating applications.

Vortex Tubes offer precise temperature control, rugged industrial construction, and long service life, making them a dependable solution for harsh environments where traditional cooling methods are impractical.