Our range of industrial air compressors is engineered for maximum durability, efficiency, and continuous operation. Whether you need a compact workshop model or a high-capacity industrial unit, our compressors deliver consistent airflow, optimized performance, and long-term reliability. Designed for low maintenance and high productivity, they support a wide range of industries including manufacturing, automotive, food processing, and more.

Key Benefits:

-

Exceptional energy efficiency and reduced operating costs

-

Heavy-duty construction for long service life

-

Stable, continuous compressed air supply

-

Low noise and vibration levels

-

Easy access for maintenance and servicing

-

Ideal for small workshops to large industrial plants

Compressors

-

Rotary-screw compressors

-

Oil-free compressors

-

Reciprocating (Piston) compressors

-

Portable compressors

-

High-pressure booster compressors

Rotary-Screw Compressors

Rotary screw compressors provide a dependable source of high-quality compressed air for industrial, commercial, and workshop applications. They are the preferred choice for environments requiring stable pressure and long, continuous duty cycles.

To maximise energy performance, these compressors utilise advanced SIGMA Profile rotors, which are precisely engineered to reduce power consumption by up to 15% compared with conventional rotor designs. This optimisation delivers higher output with significantly lower operating costs.

Each SIGMA Profile airend is manufactured for exceptional service life, featuring generously sized, precision-aligned roller bearings that ensure smooth, efficient operation. Combined with advanced in-house production processes and extremely tight manufacturing tolerances, these compressors deliver superior durability, reliability, and long-term efficiency.

Key Benefits:

- Consistent pressure for continuous-duty applications

- SIGMA Profile rotors reduce energy use by up to 15%

- Lower long-term operating and lifecycle costs

- Precision-engineered airends for extended service life

- High reliability backed by advanced manufacturing tolerances

Oil-Free Compressors

KAESER’s oil-free compression rotary screw compressors are engineered specifically for environments where absolute air purity is non-negotiable. Every component—from the materials selected to the precision of the manufacturing process—is optimised to meet the stringent requirements of clean-room production and other sensitive applications.

These systems eliminate any risk of oil contamination, ensuring consistently pure, high-quality compressed air suitable for industries such as pharmaceuticals, food and beverage processing, electronics manufacturing, and medical facilities. KAESER’s meticulous production standards are independently validated by TÜV Rheinland, ensuring full compliance with recognised quality and purity certifications.

Key Benefits:

-

100% oil-free, contamination-free compressed air

-

TÜV Rheinland certified for purity and reliability

-

Ideal for sterile, hygienic, and clean-room environments

-

Advanced materials and precision manufacturing

-

Reduced risk, improved quality assurance in production

Reciprocating (Piston) Compressors

Reciprocating compressors are engineered for demanding environments where air consumption varies throughout the day. With an optimal duty cycle between 60% and 70%, they are the ideal choice for applications that experience frequent start-stop intervals or sudden load peaks—especially in workshops, trades, and small industrial facilities.

These compressors excel at delivering high-pressure performance while maintaining durability and low operating costs. When integrated as booster units, reciprocating compressors can elevate existing system pressure to as high as 45 bar, enabling high-pressure air supply for specialised workstations or equipment without requiring a complete system redesign.

KAESER’s range includes portable reciprocating compressors designed for mobility and reliability on construction sites and commercial operations. The i.Comp series provides constant pressure up to 11 bar, available in both PREMIUM and CLASSIC configurations, with displacement capacities ranging from 130 to 660 l/min and pressure ratings between 10 and 25 bar.

Key Benefits:

-

Optimal duty cycle for fluctuating demand (60–70%)

-

Ideal for workshops, trades, and small industry

-

Booster capability up to 45 bar

-

Portable models for on-site applications

-

i.Comp units with constant pressure up to 11 bar

-

Rugged design with long service life

-

Efficient performance for high-pressure tasks

Portable Compressors

KAESER’s MOBILAIR portable compressors are engineered to deliver high performance, reliability, and exceptional versatility across construction sites, industrial environments, and remote work locations. Manufactured in Germany, these units cover an extensive output range—from compact 1 m³/min models to oil-free systems delivering up to 45 m³/min—ensuring the right solution for almost any application.

Built for heavy-duty, continuous operation, MOBILAIR compressors perform consistently even under harsh climatic conditions, extreme temperatures, high humidity, and altitudes up to 3000 m. Select models feature a rugged polyethylene enclosure, providing superior impact resistance and long-term value retention.

Whether powered by a diesel engine (including high-sulphur diesel compatibility) or an electric motor, each unit can be customised with a wide range of equipment options. Designed for user convenience, these compressors offer excellent accessibility for maintenance, simplifying service tasks and reducing downtime.

Every compressor is built around KAESER’s core principle: more compressed air with less energy—delivering sustainability, operational efficiency, and long-term performance.

Key Benefits:

-

Consistent, dependable compressed air for continuous duty

-

Engineered for harsh environments and extreme climates

-

Wide output range from 1 m³/min to 45 m³/min

-

Rugged polyethylene enclosure for long-term durability

-

Customisable configurations for any application

-

Easy access for fast, efficient maintenance

-

Global service support and long-term spare parts availability

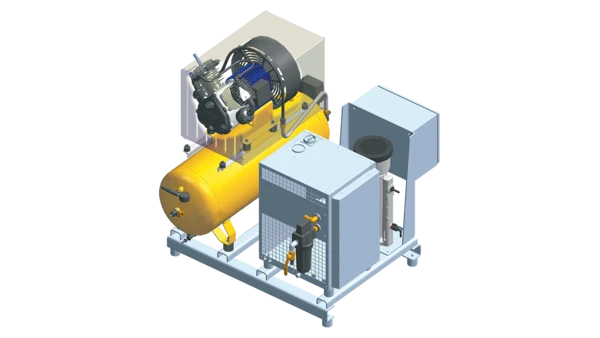

High-Pressure Booster Compressors

Many production environments only require high-pressure air at specific stages—not across the entire system. In these cases, installing a dedicated booster is significantly more efficient than designing a full high-pressure compressed air network. Booster compressors elevate existing system pressure precisely where required, ensuring optimal performance with minimal energy waste.

Our high-pressure booster range includes individual components as well as complete turnkey packages. The latest DN 22 C–DN 45 C compact booster systems combine all essential components into a single, space-efficient unit. Engineered for quiet operation, easy maintenance, and dependable output, these systems deliver constant pressure up to 45 bar and can be configured to meet the needs of different applications and installation environments.

Every system is fully ready for integration with the SIGMA CONTROL 2 controller, enabling enhanced monitoring, operational safety, and intelligent pressure management.

Key Benefits:

-

Delivers targeted high-pressure output up to 45 bar

-

More efficient than full high-pressure system design

-

Compact, all-in-one booster package available

-

Flexible configuration for various applications

-

Maintenance-friendly and quiet operation

-

SIGMA CONTROL 2 ready for intelligent control