Water, oil, and dust are the enemies of any compressed air system. KAESER’s comprehensive air treatment and filtration components are engineered to combat these contaminants, ensuring consistently dry and pure air for every application. From simple construction site usage to highly sensitive electronics production, our systems deliver outstanding protection and maintain high product quality throughout your operations.

By integrating advanced dryers, filters, and condensate management solutions, KAESER helps maintain faultless, low-maintenance processes while supporting safe and compliant condensate disposal. These components are designed to maximise system reliability, minimise downtime, and reduce overall operational costs, making them a smart long-term investment for any facility.

Key Benefits:

-

Clean, moisture-free compressed air for sensitive applications

-

Prevents corrosion and reduces equipment downtime

-

Enhances system efficiency and lifespan

-

Complies with environmental and safety standards

-

Wide range of filtration and condensate solutions

-

Low-maintenance and highly efficient

Air treatment & condensate technology

-

Air dryers

-

Filtration

-

Condensate drains

-

Start control

-

Line filter

Air Dryers

Kaeser compressed air dryers are engineered to deliver perfectly dried compressed air for any application and flow rate. Built as high-quality industrial machines, they provide reliable protection against condensate damage, safeguarding your systems and processes even under the harshest operating conditions.

To optimise long-term efficiency, these dryers feature intelligent energy-saving control for all drying processes. We work with you to identify the ideal unit size and configuration, ensuring maximum performance while keeping operating costs advantageous over the lifetime of your system.

Key Benefits:

-

Ensures consistently dry, high-quality compressed air

-

Protects systems and processes from condensate damage

-

Suitable for all flow rates and industrial applications

-

Intelligent energy-saving controls reduce operational costs

-

Optimised unit sizing and configuration for maximum efficiency

-

Reliable performance even in harsh conditions

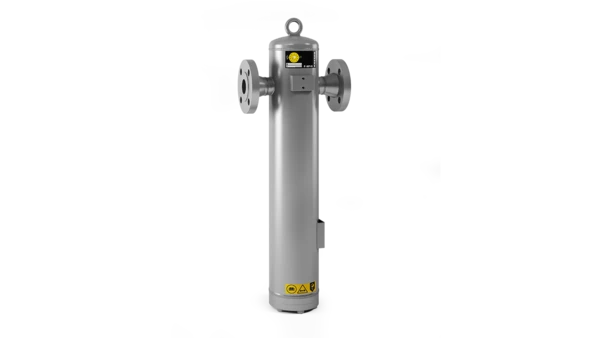

Filtration

Kaeser compressed air filters and activated carbon adsorbers deliver dependable protection against dust, aerosols, and oil vapours, ensuring your systems and processes receive pure, high-quality compressed air. Designed for all purity classes according to ISO 8573-1, these filtration solutions integrate seamlessly with our range of compressors and other compressed air treatment equipment.

Filters are available for standard pressures up to 16 bar, while high-pressure variants can handle up to 45 bar. Special silicon-free versions are also available, making them suitable for sensitive applications such as painting and coatings.

Key Benefits:

-

Protects systems from dust, aerosols, and oil vapours

-

Compatible with all compressors and treatment components

-

Meets ISO 8573-1 purity classes

-

High-pressure options up to 45 bar

-

Silicon-free models available for sensitive applications

-

Improves system reliability and product quality

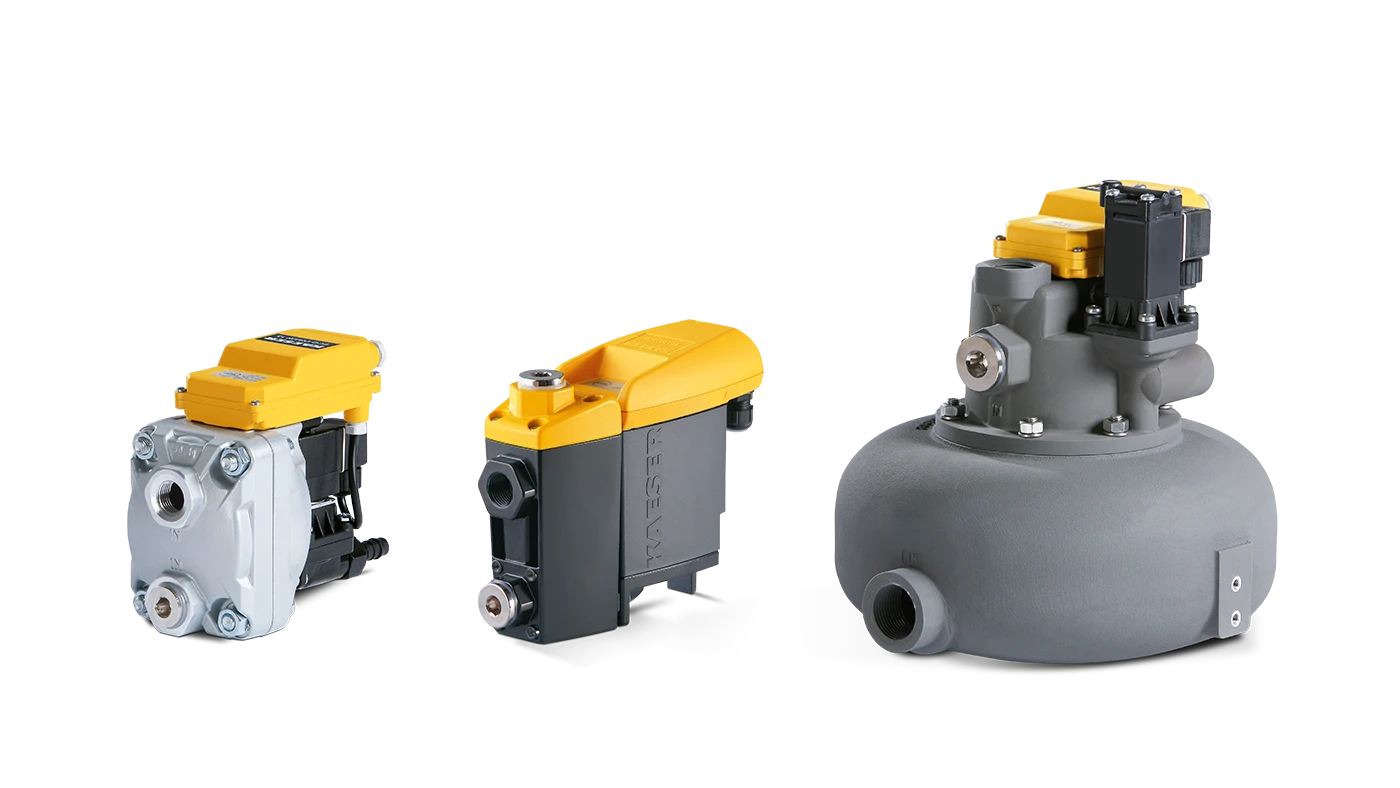

Condensate Drains

Condensate drains are essential components for efficient compressed air treatment, removing condensate from centrifugal separators, air receivers, refrigeration dryers, and filters to ensure disruption-free compressed air supply. KAESER’s ECO-DRAIN electronic condensate drains combine reliability, cost-efficiency, and intelligent control to maximise system performance.

The ECO-DRAIN system operates independently of condensate volume, utilises dirt-resistant valve mechanics, and features network-capable alarm contacts (from model 31 upwards). Suitable for compressor flow rates up to 1700 m³/min, KAESER also provides specialized versions for aggressive condensate, high pressures up to 63 bar, vacuum applications, and frost-prone environments. Intelligent electronics ensure condensate is discharged without any compressed air loss, saving energy while maintaining reliable operation even in heavily soiled conditions. Maintenance is straightforward, with pre-assembled service units that can be replaced easily without specialist support.

Key Benefits:

-

Zero compressed air loss thanks to intelligent valve control

-

Reliable drainage in heavily soiled or oily conditions

-

Independent of condensate volume and system flow

-

Suitable for high pressures (up to 63 bar) and extreme environments

-

Simple maintenance with pre-assembled service units

-

Network-capable alarm contact for monitoring

Start Control

KAESER start control systems are designed to ensure smooth, efficient, and reliable compressor operation from the moment your system starts. By intelligently managing start-up sequences and load transitions, start control solutions help reduce mechanical stress, prevent pressure fluctuations, and optimise overall system performance.

These systems play a critical role in improving energy efficiency by avoiding unnecessary peak loads and ensuring compressors operate within optimal parameters. Intelligent start control also contributes to longer equipment life, reduced wear on critical components, and improved reliability across the entire compressed air system—making it an essential part of modern, efficient compressed air management.

Key Benefits:

-

Optimised compressor start-up and load management

-

Reduced energy consumption during system operation

-

Minimises mechanical stress and pressure fluctuations

-

Extends compressor and component lifespan

-

Improves overall system reliability and efficiency

-

Ideal for integrated and multi-compressor systems